- 1

Product description:

Mining flam-proof water is a underground coal mine container. The water bag which installed by the relative technology can stop the spread of the gas and the explosion; it’s material has safety performance such as inflaming resistance and anti-static.

1.Technical requirements

a. Water bag and water groove should be in accordance with this regulation, and produced in accordance with the approved samples. The outsourcing material should have certification.

b. The size of the water bag and water groove should be in accordance with chart 1, the real water volume should be within the nominal volume.

Chart 1

|

Items Model Name |

Nominal volume (L) |

Length (mm) |

Width (mm) |

Height (mm) |

Dimension deviation (mm) |

|

|

Water groove |

GS40-4A |

40 |

Upper surface 570 Down surface 510 |

Upper surface 390 Down surface 350 |

210 |

±10 |

|

PGS-40 |

Upper surface 610 Down surface 563 |

Upper surface 386 Down surface 340 |

||||

|

GS80-4A |

80 |

Upper surface 760 Down surface 690 |

Upper surface 470 Down surface 410 |

260 |

||

|

Water bag |

GD30 |

30 |

450 |

400 |

250 |

±10 |

|

GD40 |

40 |

600 |

400 |

250 |

||

|

GD60 |

60 |

900 |

400 |

250 |

||

|

GD80 |

80 |

800 |

500 |

300 |

||

The performance of water distribution should be in accordance with the following requirements:

1-The blast pressure for water groove cracking (indicated by static pressure) should be within 16kPa; the blast pressure of water bag cracking (indicated by static pressure) should be within 12kPa;

2-The time for forming the best spray should be within 150ms;

3-The best spray lasting time: no less than 250ms for water groove, no less than 160ms than water bag;

4-The best spray distribution length should be no less than 5m.

5-The best spray distribution width should be no less than 5m.

6-The best spray distribution height should be no less than 5m.

Blast performance should be in accordance with the following requirements: The blasting flame should be with 140m include the blast source.

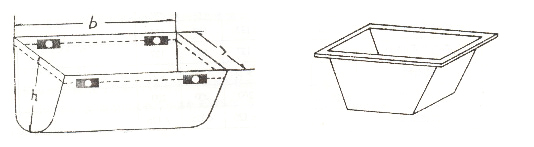

2. Structure: YS water bag, long groove shape, semi-circle bottom with firm cohere, smooth and clean surface are as picture1; YS water groove, rectangle shape, one forming, smooth surface are as picture 2.

3. Application method

a. Water shed consumption:

The flame-proof water bags (grooves) have centralization and decentralization types (according to the distribution mode).

The centralization water consumption is calculated by fracture surface square. The main water shed is no less than 400L/m2; the corollary water shed is no less than 200L/m2;

The decentralization water consumption is calculated by the taking-up lane volume, it is no less than 1.2L/m3.

b. Water shed location:

1-The water bag (groove) should be located inside the straight tunnel line;

2-The water bag (groove) intersects with the tunnel. The turning distance should be kept at 50-70m, the distance from the wind door should be no less than 25m;

3-The water shed in the first concentrated row should be kept 60-200m from working surface, the water shed in the first non-concentrated row should be kept 30-60m from working surface;

4-Locate several groups of water sheds in the corollary flame-proof water shed tunnel. Each distance should be within 200m;

c. Water shed distance and length:

1-The row distance of concentrated water shed is 1.2-3.0m, the non-concentrated water sheds are distributed along the tunnels, Distance between two water bags (grooves) is 10-30m;

2-The shed length of concentrated water shed should be no less than 30m, the length of concentrated corollary shed should be no less than 20m, the length of non-concentrated shed should be no less than 200m.

4. Installation method

a. Installation method: hang up type, pop up type, mix type; principle is that the water will spill out caused by the blast impact; arrangement should be in accordance with the following regulations:

Fracture surface S<10m2, NB/L×100> =35%

Fracture surface S<10m2, NB/L×100> =50%

Fracture surface S<10m2, NB/L×100> =65%

N-water bags number in the water shed, B-width of fracture surface in water shed, L-horizontal width of the tunnel where water shed exists.

b. The sum of the clearance between water groove (bag) and clearance between water groove (bag) and support or wall should be within 1.5m and should not surpass 1.8m. Clearance between two water groove (bag) should be within 1.2m, distance between water bag (groove) and wall, support, top plate and construction building should be no less than 0.1m, distance between water groove (bag) bottom and top beam should be within 1.6m, add a new one on the top of the water bag if the distance surpass 1.6m.

c. Distance between water shed and tunnel rail surface should be within 1.8m. The height should be kept same. Fracture surface of the tunnel should be the same as its former and back tunnel fracture surface from 20m away if there’s need for top brushing.

d. Hang up the water bag (groove) on the right position. Make the hook row at 4-8mm, the hook angle at 60±5°, change the hook at 25mm.

5. Management and notice of the water groove (bag)

a. Keep the ruled water quantity. Horizontal upper limb is the required state.

b. Check it for every 15 days.

c. The water bag (groove) is for flame-proof.

6. Package ,Transportation and Storage

a. The package should be in accordance with the relative regulations of railway and highway transportation (100 water bag belongs to 1 packet, packed by woven bags).

b. During the transportation, the water bags should be prevented from impact and friction, and kept from sun and rain.

c. The products should be storage in the storeroom with good ventilation. The stacking should not be too high so as to avoid its usage quality. Clean and dry the ducts after work, then fold and storage them. Contact with any materials which is harmful to rubber or plastic is forbidden. Keep them from sun and rain. The storeroom temperature should be kept within -15℃-35℃, relative temperature should be within 47-75%. Keep more than 1m from heat source.

d. The flame-proof water bag should have inflaming resistance and anti-static performance. It must have the relative promised water loading volume without any leakage.

e. Different water bags can be manufactured by requirements. The two sides can be installed with wind buckles. S shape link can be installed in order to make it easy to work in the water shed. Some relative iron string need to be added into two sides of water bag, thus can strengthen water bag loading ability.

f. The water bag must hang up tightly and evenly. Hang it up while there’s buckle.